Oral Biosciences – This division is responsible for Laboratory based research in Oral Microbiology and Material Science – BurButler Report

Professor David Coleman, Head of Division, Dublin Dental Hospital

www.dentalhospital.ie/clinicalacademic-divisions-and-hospital-departments/oral-biosciences

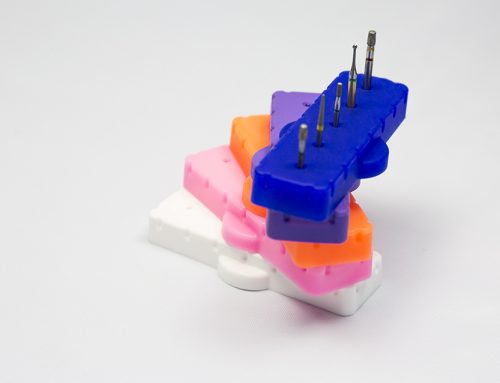

Repeated autoclaving of BurButler

A BurButler packaged in a separate porus load self sealing sterilisation pouch (Defend, Mydent International, New York, USA) on each occasion was subject to 40 consecutive rounds of autoclaving at 121°C with a hold time of 16 minutes in an independently validated vacuum steam steriliser in accordance with the requirements of the standards EN 285 and EN ISO 17665, part 1.

Following completion of each cycle, where sterilisation conditions were achieved, the BurButler was removed from its packaging and examined for integrity. On each occasion, no detectable damage to the BurButler was observed following careful physical examination. Similar results were observed following 10 separate sterilisation cycles at 134-137°C with a minimum 3 minute hold time.

Washer-Disinfector

A BurButler was processed in a washer-disinfector conforming to EN15883. Twenty consecutive cycles were performed with thermal disinfection at 90°C for 1 minute on each occasion. Following processing, the BurButler examined for integrity. On each occasion, no detectable damage to the BurButler was observed following careful physical examination.

Removal of contamination from a BurButler by a Washer-Disinfector

For convenience of processing, a BurButler was separated into its two constituent halves using a sterile scalpel. The halves were used for the experiments described below. Standard cell suspensions of Pseudomonas aeruginosa strain PAO1 (108 cfu/mL) prepared from fresh overnight (15 h) cultures grown on Columbia Blood Agar (CBA) medium at 30°C were made in sterile phosphate buffered saline (PBS) (Sigma-Aldrich, Ireland Ltd.) and 100 μl aliquots inoculated onto the surface of a BurButler and allowed to dry at ambient temperature for 20 min. Immediately afterwards, the BurButler was processed through a washer-disinfector.

Following processing, the BurButler was completely immersed in sterile PBS in a sterile plastic beaker containing a stirring flea and stirred on a magnetic stirrer at room temperature for 30 min. Then the liquid was centrifuged to recover any bacterial cells, the supernatant discarded and 1 ml of sterile PBS added to resuspend the pelleted material. Ten-fold dilutions were prepared in sterile PBS and aliquots plated onto CBA followed by incubation overnight at 30°C. Following incubation, plates were examined for viable colonies. Experiments were repeated on 10 separate occasions.

Similar experiments to the above were undertaken (n=10), except the bacterial cells were resuspended in PBS supplemented with 2 mg/ml bovine serum albumin (Sigma-Aldrich) prior to inoculation onto BurButler halves.

No viable P. aeruginosa were recovered following washer-disinfection in any of the experiments described above.

BurButler processing by steam sterilisation

BurButler halves inoculated with P. aeruginosa PAO1 resuspended in PBS supplemented with BSA (2 mg/ml) were packaged in autoclave pouches and processed in a steam steriliser (121°C with a hold time of 16 minutes) in accordance with the requirements of the standards EN 285 and EN ISO 17665, part 1. Following processing, BurButler halves were removed from their pouches and subjected to immersion in sterile PBS as described in the preceding paragraph. No viable P. aeruginosa were recovered in each of 15 separate experiments.

Separate experiments were undertaken with BurButler halves containing 8 steel burs, the shanks of which had been dipped into a suspension ofP. aeruginosa PAO1 (108 cfu/mL) in PBS supplemented with BSA (2 mg/ml). The BurButler halves were immediately packaged in sterilisation pouches and and processed in a steam steriliser (121°C with a hold time of 16 minutes). Following processing, each bur was removed and placed aseptically into 5 ml of Trypticase Soy Broth in a sterile plastic test tube and incubated overnight with shaking at 150 rpm. Following incubation, each tube was examined for viable P. aeruginosa by culture on CBA medium.

No viable P. aeruginosa were recovered from each of the 8 burs tested on 8 separate occasions. Furthermore, no viable P. aeruginosa were recovered from the BurButler halves from which the steel burs had been removed following immersion in PBS as described above.

Conclusion

The BurButler is a robust item that retains its integrity following repeated steam sterilisation and processing through a washer-disinfector. Washer-disinfection is ideal for removal of microbial contamination and in the presence of protein.

The BurButler is ideal for sterilisation by steam sterilisation. I recommend that the BurButler should be cleaned and disinfected regularly by washer- disinfection. The BurButler can then be loaded with clean burs and sterilised by processing in a steam steriliser.

Pseudomonas aeruginosa strain PAO1

(American Type Culture Culture strain 15692) http://www.uniprot.org/taxonomy/208964) is routinely used for testing the efficacy of disinfectants and disinfection processes.